A college building with a teaching tool as a design feature, a 1960s office building modernized with new steel elements, and the world's largest spherical structure are among the 2025 AISC IDEAS² Award recipients.

Five recent projects have earned one of the steel industry's most notable honors: an Innovative Design in Engineering and Architecture with Structural Steel (IDEAS²) Award.

AISC annually presents the IDEAS² Awards to projects that illustrate the many possibilities of building and designing with structural steel.

The awards display innovative steel use in the accomplishment of the structure's program, the expression of architectural intent, the application of innovative design approaches to the structural system, and leveraging productivity-enhancing construction methods.

Many IDEAS² winners are landmark structures, but the program also honors smaller, less visible projects. No matter the project size or fame, all winning structures share a commitment to innovation and imaginative design.

Hear directly from the 2025 IDEAS² Award judges about what makes these the most innovative projects in America!

Excellence in Architecture

Pima Community College - Advanced Manufacturing Center

Tucson, Ariz.

An Arizona community college's new campus centerpiece incorporates key learning tools into its design, an architectural and engineering innovation only possible with a structural steel system that helped complete the project under budget.

Looking to solve the shortage of qualified workers in local industries, Pima Community College in Tucson, Ariz., opened the Center of Excellence for Applied Technology, which includes the 95,000-sq.-ft Advanced Manufacturing Building (AMB).

The three-story industrial learning facility has space to teach welding, machine tools, mechatronics, and CAD, among other trades. It also has a workforce development incubator, a flexible industry training lab, administrative offices, and a rooftop patio for outdoor learning and events.

The AMB features a centralized circulation spine that is connected visually and functionally by a 10-ton underslung bridge crane, which transverses the entire building length above the exterior walkways and connection spaces. The crane, which can transport materials throughout the facility, provides a visual cue for students to see and understand the connections between the various learning pathways.

"The elevated crane bay connecting the length of the building puts the structure on display and becomes this iconic and unifying feature that reinforces the idea of bringing partners together in education, industry, and community."

The main structural system is comprised of composite floor deck supported by wide-flange steel beams and columns, as well as metal roof deck. Hollow structural sections (HSS) braced frames comprise the lateral load system. The crane runway beam is supported by the main building columns instead of a separate supporting structure. The structural steel system was the only choice for this unique design because of its economy, aesthetics, and flexibility.

Owner: Pima Community College, Tucson, Ariz.

General contractor: Chasse Building Team, Tucson, Ariz.

Architect and structural engineer: DLR Group, Phoenix

Credit for images 1-3: Kyle Zirkus; credit for image 4: Matthew Winquist

Excellence in Adaptive Reuse

Top of The Rock Redevelopment

New York

Image 1 courtesy of Tishman Speyer; credit for images 2 and 3: Mike Pugliese; credit for image 4: Nick Zickgraf

An iconic New York City building added attractions to its popular rooftop observation area, and the project's new steel elements facilitated disruption-free work and success on a tight rooftop jobsite.

The owners of Top of The Rock on the 67th, 69th, and 70th floors of 30 Rockefeller Plaza in midtown Manhattan wanted to bring new interactive experiences to the observation deck. One is called The Beam and allows patrons to recreate the famous "Lunch Atop a Skyscraper" photograph from the 1930s. The other, the Skylift, is a telescoping platform that rises 30 ft above the 70th floor and provides panoramic city views.

The observation deck could not close during the construction of both rides and the frame adjustments to accommodate them, and work could not interrupt the building's elevators despite a lack of freight elevator access to Top of The Rock.

Luckily, choosing steel for the additions and modifications allowed the structural engineer to work more efficiently with Rockefeller Center, which was constructed with a steel frame. The range of available steel shapes and sizes allowed for creative use of new sections and reinforcement.

"It's not easy to rig an amusement ride at the top of an existing 90-year-old building. The ride captures the spirit of steel and the ironworkers who have brought it to life through the ages to celebrate the connection between a community and the structures that define it."

This project would have been easier to execute if the observation deck could have closed for a few months to accommodate blowing out existing bays and bulkheads and replacing them with a purpose-built frame, but that wasn't an option. Deliberate coordination, creative engineering, and working with an adaptable material resulted in a project whose original structure, designed for one purpose, could be elegantly altered for a completely new one.

Owner: Tishman Speyer, New York

General contractor: Gilbane Building Company, New York

Architect: Montroy DeMarco Architecture LLP, New York

Structural engineer: Gilsanz Murray Steficek, New York

Attraction consultant: THG Creative, Pasadena, Calif.

Steel team:

Fabricator and detailer: North American Manufacturing Corp. *AISC full member; AISC-Certified fabricator*

Erector: Maspeth Welding, Inc., Maspeth, N.Y.

Excellence in Constructability

200 Park

San Jose, Calif.

The tallest building in San Jose, Calif., is also the state's first of its kind. The 19-story, 300-ft office tower known as 200 Park became the first California building—and second anywhere—to use the SpeedCore structural system.

Steel was the unquestioned choice to achieve the building's open layout, which includes outdoor terraces on about half the levels and natural light pathways at almost every turn.

SpeedCore emerged from the project team's studies and early considerations as more cost-effective than a traditional braced frame or reinforced concrete core. SpeedCore could also be erected faster—three months faster than a traditional reinforced concrete core. Additionally, its substantial shear capacity reduced wall thickness by up to 18 in. (up to 30%) compared to a concrete core wall.

While the project was still early in the design process, Purdue University's Applied Research Institute confirmed most fireproofing could be eliminated from the core. The testing showed that walls at least 24 in. thick easily exceeded the three-hour rating. The project team presented the discovery to local building officials and was permitted to eliminate most spray-on fireproofing from the SpeedCore faces, saving the owner additional time and money.

"The SpeedCore system really set 200 Park apart in constructability. SpeedCore offers schedule efficiency and reduction of fireproofing based on the system thickness. More importantly, it offers a reduced level of high-risk safety activities associated with traditional concrete cores."

The building was completed in May 2023, and SpeedCore was the primary reason behind its three-month time savings compared to a traditional frame. It finished a month earlier than the initial SpeedCore schedule. It was speculatively designed, making it an attractive space for a wide tenant range now and in the future.

Owner: Jay Paul Company, San Francisco

General contractor: Level 10 Construction, Sunnyvale, Calif.

Architect: Gensler, San Francisco

Structural engineer: Magnusson Klemencic Associates (MKA), Seattle

Steel team:

Fabricator and erector: Schuff Steel Company *AISC full member; AISC-Certified fabricator and erector*

Detailer: DBM Vircon, Tempe, Ariz. *AISC associate member*

Erection and construction engineer: Simpson Gumpertz and Heger (SGH), San Francisco

Connections consultant: Steel Structures Technology Center, Inc., Howell, Mich.

Credit for images 1 and 2: Jason O'Rear / Level 10 Construction; credit for all other images: Schuff Steel Company

Excellence in Engineering

Penn 2 Redevelopment

New York

Credit for all images: Severud Associates

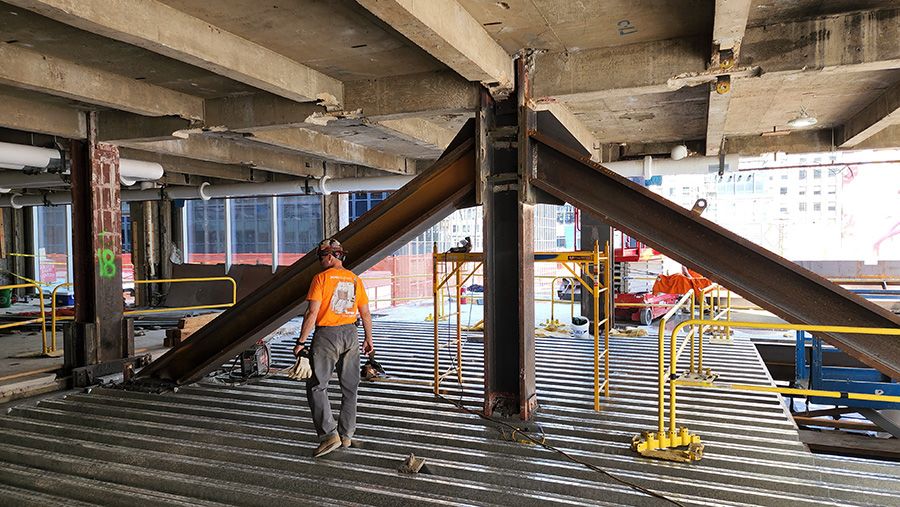

A midtown Manhattan office building needed a boost from its original 1960s form, and its steel frame lent itself to adaptation and longevity despite its age.

New steel elements incorporated at PENN 2 created a 75-ft by 450-ft addition called the Bustle that hovers 50 ft above the sidewalk on 14 dramatically sloped columns configured around an existing trainshed. Creative connections ensured the existing structure and addition do not transfer significant lateral load to each other.

The Bustle goes from the fourth to 10th floor and provides 100,000 sq. ft of double-height, column-free office space, 43,800 sq. ft of roof terraces, and an expansive, protected public plaza adjacent to Seventh Avenue. It takes advantage of the existing building's setback from Seventh Avenue by using space not embraced in the 1960s design.

Several years of conceptual studies and design development resulted in minimal disruption to the existing transit facilities and the hundreds of thousands of travelers who use them daily. Documentation of existing structures, including field surveys and material testing, combined with sophisticated analysis and advanced materials, allowed a modern addition to be built atop a century-old trainshed structure.

"The engineering team overcame so many intricate and complex design challenges while working within the constraints of the existing structure. . . . The strategically placed connections between the addition and the existing structure ensured a balanced lateral system without transferring significant load between either system."

Structural steel was the natural choice for the project. The triple-height entrance lobby, double-height corner loggias, and roof terrace and pavilion were created by selectively demolishing entire framing bays—except for members bracing existing columns—and reinforcing the columns for the increase in unbraced length.

Owner: Vornado Realty Trust, New York

General contractor: Turner Construction Company, New York

Architect: MdeAS Architects, New York

Structural engineer: Severud Associates Consulting Engineers, New York

Steel team:

Fabricator and detailer: Crystal Steel Fabricators, Delmar, Del. *AISC full member; AISC-Certified fabricator*

Erector: Skanska USA Civil Northeast, Inc., East Elmhust, N.Y.

Casting supplier: CAST CONNEX, Toronto *AISC associate member*

Presidential Award for Engineering Design and Construction

Sphere

Las Vegas

The largest spherical structure in the world is a display of groundbreaking steel innovation that has helped redefine the immersive entertainment experience.

Sphere, the next-generation music and performing arts venue just east of the Strip in Las Vegas, is a 516-ft-diameter semi-spherical building rising 366 ft above ground. It encloses a bowl-shaped theater for 17,600 guests seated beneath a domed roof and a suspended media plane.

Sphere visitors first encounter the exosphere, the venue's outer latticed grid shell composed of steel pipe sections and cast steel connecting nodes and covered with 580,000 sq. ft of programmable LED lighting. The structural engineers employed parametric design and optimization to determine the sphere's lightest tessellation. They also found significant benefits with cast steel nodes, a crucial project component.

Inside the venue, the upper seating framing and perimeter concourses are structural steel in a barrel-shaped arrangement. An optimized steel-framed dome tops off the theater.

The project also includes a separate collar structure with the loading dock and other back-of-house facilities, plus a 1,200-ft serpentine pedestrian bridge framed with steel box trusses that connects the venue to a convention center. A bridge building provides a transition to the venue. The bridge and collar buildings are isolated from the exosphere.

"Detailing in two dimensions is already complicated, but bringing to life this three-dimensional geometry was even more commendable. This project exemplifies the kind of creativtiy and collaboration that will set the standard for future wonders like this one."

Although Sphere is composed of distinct structural systems, they are all interconnected to form a cohesive, balanced, efficient, and elegant superstructure. Sphere aimed to create a fully immersive experience and elevate in-person entertainment to new levels. The $2.2 billion facility took five years to construct and opened in September 2023.

Owner: Sphere Entertainment Co., New York

General contractor: MSG LV Construction, LLC, Las Vegas

Architect: Populous, New York

Structural engineer: Severud Associates Consulting Engineers, New York

Steel team:

Fabricator and erector: W&W | AFCO Steel, Oklahoma City *AISC full member; AISC-Certified fabricator and erector*

Detailer: Pro Draft, Inc., Surrey, B.C. *AISC associate member*

Bender/rollers: Chicago Metal Rolled Products, Chicago *AISC associate member*; Max Weiss Company, Milwaukee *AISC associate member*

Casting supplier: CAST CONNEX, Toronto *AISC associate member*

Erection and construction engineer: Stanley D. Lindsey & Associates, Ltd. (SDL), Atlanta

Credit for first image: Sphere Entertainment Co.; credit for all other images: Severud Associates

Submit your recent project for the next IDEAS Awards!

We're looking for projects that showcase excellence in:

Adaptive reuse

Architecture

Constructability

Engineering

Sustainable design and construction

You could even get recognition for your design before the project breaks ground! The IDEAS|next Award recognizes concepts that are still on the boards.

Visit aisc.org/ideas to stay up to date with the IDEAS program.