An active taxiway crossing, a sparkling

bridge connecting two growing neighborhoods

in Washington, D.C., and several short-span

projects are among the eight structures to receive 2024 AISC/NSBA Prize Bridge Awards.

Innovation abounds in the steel bridge industry. Eight recent bridge projects are especially captivating showcases of it.

AISC and the National Steel Bridge Alliance (NSBA) handed out the 2024 Prize Bridge Awards to eight recently completed structures, from short creek overpasses to major river crossings and even a taxiway bridge at an airport.

More than 600 bridges of all sizes from all four North American time zones have earned this award since 1928, when AISC gave the inaugural honor to Pittsburgh’s Sixth Street Bridge. Some of those long-ago winners are still in service and have even outlasted the companies that built and designed them.

Learn more about the most innovative bridges in America—and one game-changing Department of Transportation.

AISC and NSBA honored the Texas Department of Transportation (TxDOT) with the inaugural Owner of the Year Award.

A lot goes into an innovative bridge—from economics, design, and research to engineering solutions and project delivery methods—and the new Owner of the Year Award recognizes extraordinary bridge owners whose vision and dedication move the industry forward.

"TxDOT isn't just implementing best practices for designing and building steel bridges—it is defining how an owner can maximize the potential of steel," said NSBA Senior Director of Bridge Initiatives Jeff Carlson, PE.

With a portfolio of projects such as the SH 105 Brazos River Bridge (shown below), which implements lean-on bracing for a non-skewed bridge, TxDOT's longstanding investment in steel bridge research is paying dividends not only for Texans but for anybody who travels on bridges across the United States.

"TxDOT is a big research-driven DOT," said HNTB Associate Fellow Natalie McCombs, SE, PE, a 2024 Prize Bridge Awards judge. "TxDOT helps a lot of the other DOTs that maybe don't have as much funding available for their research. This then, in turn, enhances the availability for them to use some of their details and follow their lead."

Bridge of the Year Winner

National Award, Major Span

The New Frederick Douglass Memorial Bridge

Washington, D.C.

The New Frederick Douglass Memorial Bridge is a replacement in designation only.

Yes, it technically took the place of an old structure bearing the same name crossing the Anacostia River in Washington, D.C. But it’s much more than a link between two sides. The owner and design team envisioned a structure that would fit with Washington’s timeless architecture—a bridge that is classic but not classical, dramatic but not theatrical.

The result is the one-of-a-kind, above-deck arch design that opened in September 2021, replacing a bridge built in 1950. The New Frederick Douglass Memorial Bridge (FDMB) is 1,444 ft long with two 452-ft side spans and a 540-ft center span, significantly exceeding the minimum horizontal navigation channel width to open the waterway for all users.

"Steel is really the perfect choice for this bridge given the slender nature of the arches. The design aesthetic they were going for really requires the high strength and light weight of steel to make it work."

Structural steel was the only solution for the bridge to achieve its signature arches, which have a variable hexagonal cross-section and a variable depth from the base to the crown. The three sets of lighted, parallel arches spring high above the water and stand out amid nearby landmarks.

The bridge provides a positive bank-to-bank connection, with the arch profile suggesting the path of a stone skipping across the water. Unlike other Washington, D.C. arch bridges, the intent behind this design was to extend the arches vertically above the deck to create a landmark structure.

Owner: District of Columbia Department of Transportation, Washington, D.C.

General contractor/erector: South Capitol Bridgebuilders (SCB), joint venture of Archer Western and Granite Construction, Washington, D.C.

Structural engineer: AECOM, Glen Allen, Va.

Lead bridge architect: BEAM Architects, Bridgport, U.K.

Erection and construction engineer: McNary, Bergeron & Johannesen, Hartford, Conn.

General engineering consultant: HNTB, Arlington, Va.

Steel team:

Fabricator: Veritas Steel LLC, Eau Claire, Wis. and Palatka, Fla. *AISC full member; AISC-Certified fabricator*

Detailer: Tensor Engineering, Indian Harbour Beach, Fla. *AISC associate member*

Credit for all images: Robb Williamson

Merit Award, Major Span

Long Beach International Gateway Bridge

Port of Long Beach, Calif.

Credit for all images: Marie Tagudena and Nancy Henderson

The gateway to an American economic centerpiece is as architecturally striking as it is crucial to daily commerce in Southern California.

About 15% of all North American maritime container traffic crosses the Long Beach International Gateway Bridge, and freighters pass under it when entering the Port of Long Beach’s back piers. It’s a critical infrastructure link and a vital component of the regional and national economy.

The new bridge is also a landmark of a city best known for its port—and a first-of-its-kind bridge in the state.

The $1.5 billion, 9,996-ton bridge opened in 2020, replacing the 51-year-old Gerald Desmond Bridge that carried six lanes of Interstate 710 over the port’s back channel. The replacement project didn’t only create a bridge designed to last 100 years and secure long-term port access. It birthed California’s first major cable-stayed bridge and an aesthetically pleasing addition to Long Beach’s waterfront cityscape. It also pushed the envelope of seismic design for bridges.

"What the judges saw that made this project stand out was the innovative seismic design that utilizes dampers connecting the suspended steel structure to the towers. The combination of box sections and open sections was appropriate to efficently carry some of the heaviest loads in the nation."

The California Department of Transportation and the Port of Long Beach designed a two-tower, six-lane cable-stayed bridge with a 100-year service life, providing seismic resilience and adequate vertical and horizontal clearance to accommodate the newest generation of cargo ships—all within an affordability limit. Steel provided a lightweight superstructure for an economical and innovative approach to seismic design.

The final product is a 2,000-ft-long by 150-ft-wide bridge fabricated from A709 HPS-50W plate. It has fracture critical elements, trapezoidal box edge girders, I-beam floor beams, complex box end girders, pier skin plates, and cable stayed anchor boxes. A 2,000-ft bike and pedestrian structure cantilevers off the south end.

Owner: California Department of Transportation, Sacramento, Calif.

Owner's representative: Port of Long Beach, Long Beach, Calif.

General contractor/erector: SFI (Shimmick/FCC/Impregilo) JV, Irvine, Calif.

Structural engineer: Arup, New York

Steel team:

Fabricator: Stinger Bridge & Iron, Coolidge, Ariz. *AISC full member; AISC-Certified fabricator and erector*

Detailer: SSP Engineering, Queen Creek, Ariz. *AISC associate member*

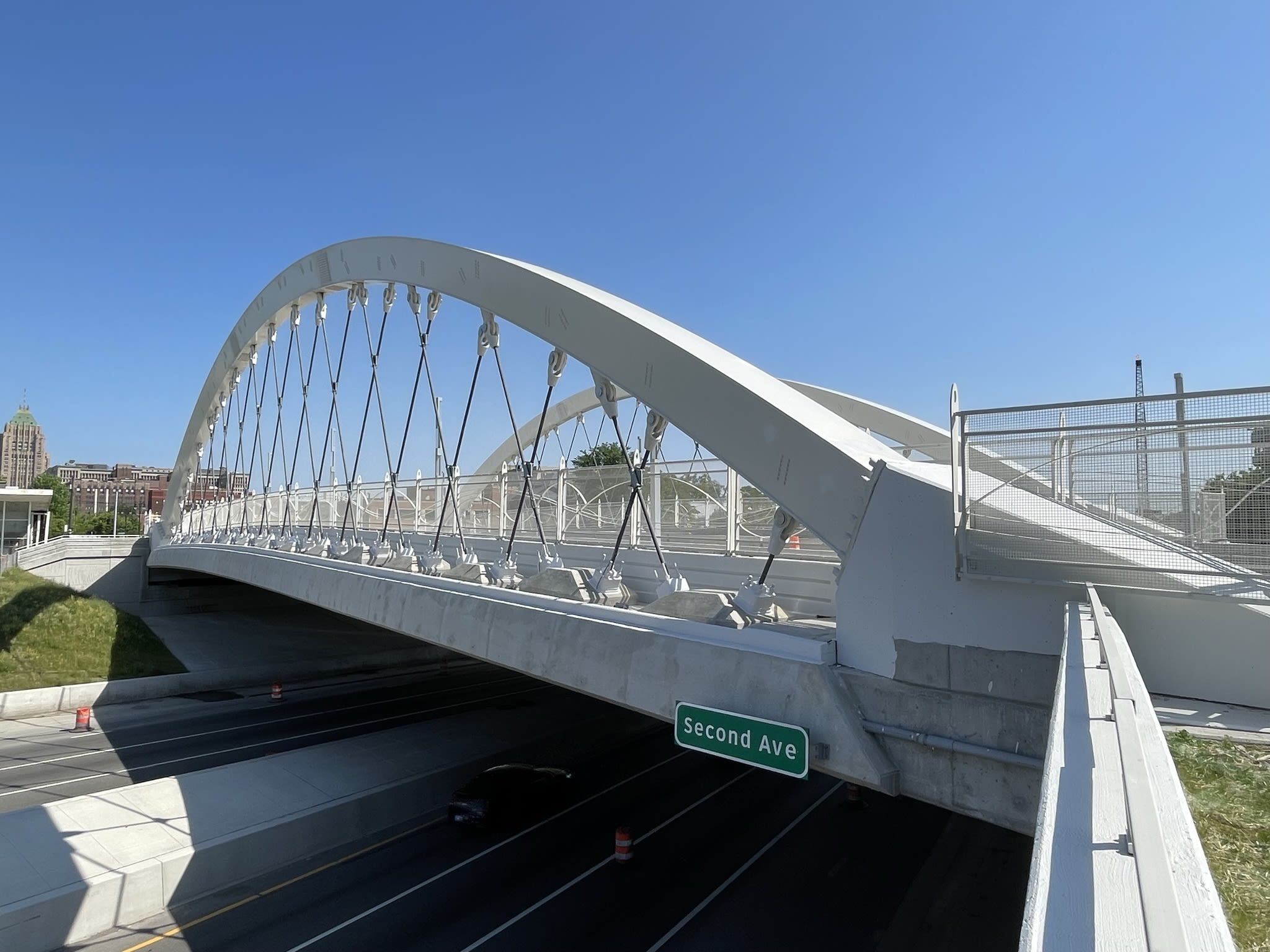

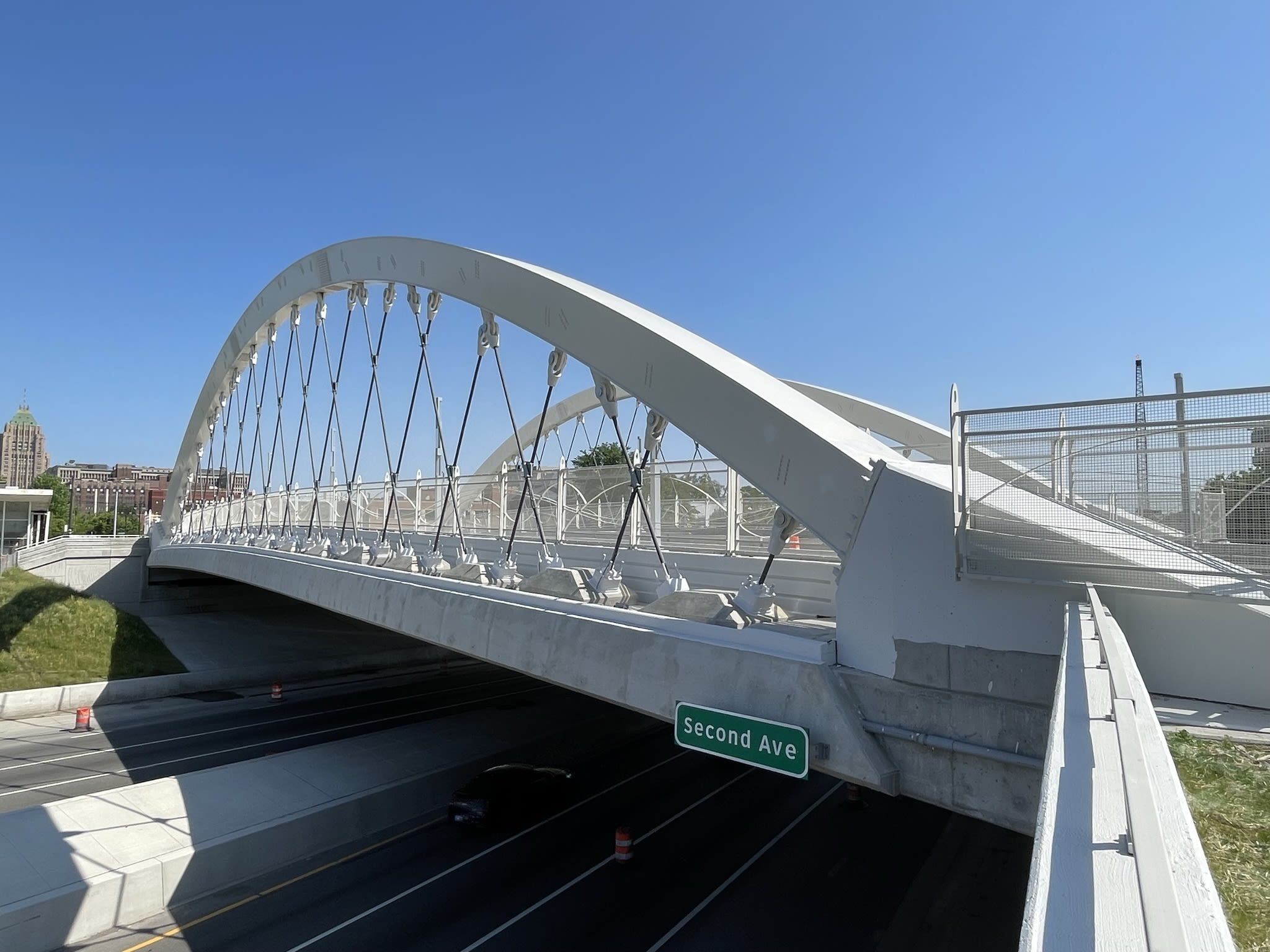

National Award, Medium Span

I-94 2nd Avenue Bridge Network Tied Arch

Detroit

A core piece of Detroit’s $2 billion Interstate 94 corridor reconstruction and downtown revitalization made history with its daring engineering.

The new 245-ft bridge carrying Second Avenue over I-94 is the first skewed and unbraced network tied arch bridge in the United States. It was also erected offsite and moved into place.

A historic building adjacent to the bridge location required an 18° skew, which offset the bridge’s arches longitudinally by nearly 30 ft. Structural steel’s strength, low weight, and flexibility were essential to reduce the bridge skeleton’s dead load and facilitate the self-propelled modular transporter (SPMT) move and installation. During the design, one of the controlling load cases was the buckling capacity of the unbraced arch ribs, and the torsional stiffness of structural steel was up to the challenge.

"If you were to install the cross bracing between the arches on the skew, it would actually have kind of a funny visual effect. By making an unbraced bridge, it really improved the aesthetics and the look of the bridge."

All told, 800 tons of AASHTO M270 Grade 50 steel make up the trapezoidal arch ribs, floor beams, and lateral bracing in the floor system. The unbraced arch ribs consist of trapezoidal box sections with PL 1¾ in. by 4¾ ft for the top flange and PL 1¾ in. by 2½ ft for the bottom flange. Web plates also consist of 1¾-in. material on a 1:3.74 inclination.

The tied arch span allowed the bridge to be constructed without the need for future demolition and reconstruction of a median pier that would have been required with a conventional steel girder bridge at that location. The tied arch spans completely over the current freeway alignment and was designed to be long enough so that the future shifted freeway will fit comfortably between the abutments, providing complete construction access for the current and future alignments.

Owner: Michigan Department of Transportation, Lansing, Mich.

General contractor: Z Contractors, Shelby Township, Mich.

Structural engineer: HDR, Ann Arbor, Mich.

Erection engineer: Janssen & Spaans Engineering, Indianapolis

Independent peer review: Parsons, Chicago

Steel team:

Fabricator: Veritas Steel LLC, Eau Claire, Wis. *AISC full member; AISC-Certified fabricator*

Detailer: Tensor Engineering, Indian Harbour Beach, Fla. *AISC associate member*

Image credit: HDR - Matt Longfield and Mike LaViolette

Merit Award, Medium Span

Rt. 34B over Salmon Creek Bridge Replacement

Lansing, N.Y.

Credit for all images: NYSDOT

A two-lane highway bridge replacement project in Central New York became a banner structure for the state.

The new State Route 34B bridge over Salmon Creek in Lansing, N.Y., keeps its predecessor’s aesthetics but is the longest and tallest slant-leg rigid frame structure in New York State. The 500-ft bridge is made of modern 50-ksi weathering steel, giving it a 100-year expected service life.

The old bridge was a three-barrel arch structure with a rustic appearance, and weathering steel was the perfect option for the replacement to mimic its look and feel as defined by the State Historic Preservation Office (SHPO). Steel provided the flexibility to design and construct a unique bridge that gives the community something worthy of replacing a Register of Historic Places-eligible structure. It also lent itself to a rapid erecting process that limited closures and detours for a central roadway in and out of the Ithaca, N.Y., region and to Cayuga Lake attractions.

"The judges were very impressed that the New York State DOT took it upon themselves to design this structure... It really fits well spanning the gorge and honoring the historic nature of this site."

By selecting a slant-leg rigid frame structure, the SHPO invited several unique design challenges. The knuckle region has a large, unbraced height and a large axial and flexural demand. The supporting legs of the structure are slanted and spring from thrust blocks embedded in the bedrock below. These legs have high axial, shear, and flexural forces, uncommon in typical steel structures. The intersection of the leg members with the roadway girders contained the highest axial and flexural forces within the structure and an extremely high web height.

The depth of the gorge the bridge crosses suited the slant-leg frame, because bedrock was relatively high and offered a sound foundation for the legs. The visual appeal when looking up from the gorge is striking.

Owner/structural engineer: New York State Department of Transportation, Albany, N.Y.

General contractor: Tioga Construction Company, Herkimer, N.Y.

Steel team:

Fabricator: Canam-Bridges, Claremont, N.H. *AISC full member; AISC-Certified fabricator*

Detailer: DBM Vircon, Phoenix *AISC associate member*

National Award, Short Span

Grand Forks County Prefabricated Bridge

Northwood, N.D.

Any new bridge spanning North Dakota's Goose River must withstand flooding and long winters—and, ideally, it’s also constructable during one of those winters.

A prefabricated steel frame ensured the refreshed 36th Street NE bridge checked all three boxes. Weathering steel beams offered durability and minimal maintenance. Steel also created flexibility in the depth of the superstructure in an area prone to flooding, the ability to clear the channel with one span, and the possibility of fabricating the superstructure offsite and delivering it in minimal pieces to install quicker and easier. The substructure used steel to help facilitate cold-weather installation and expedite the construction timeline.

The local economy is mostly agriculture-related commerce that peaks in spring and summer, and the ability to construct in the winter minimized the installation’s economic inconveniences. The bridge opened to traffic before the spring planting season.

"This bridge is innovative because it uses steel for both the superstructure and substructure. This allowed it to be constructed in the winter months."

The prefabricated bridge lent itself to completion within the sensitive construction window and the limited allowance for increasing the roadway height. Using the same size H-piles for the wingwalls and pile caps provided an economy of scale for materials.

The design team also considered concrete, but limited availability and high cost of heating during the preferred cold weather construction window made concrete less favorable than steel or timber. A timber prefabricated superstructure option was carried out through design and included in the bid package for contractors. The structural steel prefabricated bridge was the lowest bid option at the construction bid opening.

Owner's representative: Grand Forks County, Grand Forks, N.D.

General contractor: Industrial Builders Inc, West Fargo, N.D.

Structural engineer: KLJ Engineering, Grafton, N.D.

Fabricator/detailer/erector: TrueNorth Steel, Fargo, N.D. *AISC full member; AISC-Certified fabricator*

Credit for all images: Wade Thompson

Merit Award, Short Span

SR32 Bridge over Stony Creek

Noblesville, Ind.

Image credit: HNTB, University of Notre Dame, INDOT

A new bridge installed in suburban Indianapolis is part infrastructure project, part research collaboration.

And its use of steel traces directly back to a February 2018 NSBA brainstorming workshop aimed at making steel bridges more competitive in the short-span marketplace.

The workshop introduced a bolted-up tub girder concept as a strategy that capitalized on the steel industry’s ability to fabricate components on demand with steel that is already in stock. It more closely mirrors the workflow used by the precast concrete industry, which dominates the short-span bridge market. Indiana Department of Transportation (INDOT) representatives were in attendance and intrigued by the concept.

In January 2019, the University of Notre Dame, in collaboration with HNTB Corporation, pitched the same concept to INDOT. It was funded in the next fiscal year, with a start of January 2020.

Using built-up press-brake-formed tub girders (PBFTGs) to replace the State Road 32 bridge over Stony Creek in Noblesville offered just the opportunity to take the plunge.

"The Indiana DOT worked with a design consultant, a research team, fabricators, and steel producers to develop a new methodology for press brake tub girders. This extends the applicability and range of this type of structure from previous research."

Using steel was critical, but readily available steel was the essential component of condensing the project timeline and lowering costs. Leveraging the workflows and equipment that form an integral part of the fabrication of transmission poles (a nearly $3 billion North American market) was a primary goal. The project created a path for new fabricators to enter the bridge market, especially given the unprecedented funding for infrastructure in the Infrastructure Investment and Jobs Act.

The State Road 32 replacement project included a unique and collaborative delivery team of engineers, researchers, steel fabricators, and suppliers: INDOT, the University of Notre Dame, HNTB, Delta Steel, and Nucor Corporation. The team’s rare level of depth and comprehensiveness was critical to implementing a novel design concept in less than three years. Nucor and Delta Steel donated their steel and fabrication time for this project, representing a remarkable commitment from the steel industry to develop new and innovative solutions.

Owner: Indiana Department of Transportation, Indianapolis

General contractor: HIS Constructors, Inc., Indianapolis

Structural engineer: HNTB Corporation, Kansas City, Mo.

Consultants: University of Notre Dame, South Bend, Ind.; Nucor, Boise, Idaho

Steel team:

Fabrication team: Infra-Metals/Delta Steel, Houston *AISC full member; AISC-Certified fabricator*; Kard Bridge Products, Minster, Ohio *AISC full member, AISC-Certified fabricator*

Detailer: Weaver Bridge Corporation, Granville, Ohio *AISC associate member*

Galvanizer: V&S Galvanizing, Columbus, Ohio *AISC associate member*

National Award, Special Purpose

SeaTac IAF Pedestrian Walkway

Seattle

Seattle-Tacoma International Airport (SeaTac) dove into a rarely used method to get passengers across a taxiway--and raised the bar for bridge design.

Most airports move passengers from terminal to terminal with an underground walkway, a subway tram, or an elevated tram that hugs the terminal buildings. Port of Seattle, which owns and operates the airport, chose the most direct but difficult concept: an overhead bridge crossing an active taxiway.

Only two other airports in the world have previously built a bridge over a tarmac. Seattle’s new bridge outdid both. Its 780-ft walkway is the world’s largest structure over an active taxiway. Its 610-ft span also represents the longest clear-span structure at an airport. If stood vertically, it would be 150 ft taller than the Space Needle. It’s a direct and efficient route for international passengers to reach the International Arrivals Facility, which houses customs. Stunning views of the Pacific Northwest and Mt. Rainier greet travelers as they ascend its escalators and walk across it.

"Normally, cable-stayed bridges accentuate the structure, but here, it's inside an enclosed walkway. [The structure] is muted, but the discerning eye should be able to pick it up."

The bridge took eight years to plan, design, and construct. Steel was the material of choice due to the clear span length, seismic criteria, and need for innovative design and construction methods. The walkway contains 3,000 tons of steel, while the cores use another 160. It has 800 tons of rebar and a 2,200-ft cable length. Its 191-ft escalators are among the 10 longest in the United States. Steel V-Piers support the pedestrian bridge at either side and allow the bridge to have an 85-ft clearance from the bottom deck to the tarmac, enough room to fit a Boeing 747.

Owner: Port of Seattle, SeaTac, Wash.

General contractor: Clark Construction, Seattle

Structural engineer: KPFF, Seattle

Steel fabricators:

Thompson Metal Fab, Vancouver, Wash. *AISC full member; AISC-Certified fabricator*

Jesse Engineering, Tacoma, Wash. *AISC full member; AISC-Certified fabricator*

Transco Industries, Portland, Ore. *AISC full member; AISC-Certified fabricator*

Greenberry Fabrication, Vancouver, Wash. *AISC full member; AISC-Certified fabricator*

Image credit: SOM, Port of Seattle

Merit Award, Special Purpose

South Bayfront Pedestrian Bridge and Horton Landing Park

Emeryville, Calif.

Credit for all images: Tom Loomis

A rail yard essentially sliced Emeryville, Calif., into two pieces for pedestrians and cyclists—and the South Bayfront Pedestrian Bridge tied those pieces back together.

The area had bridges over the sprawling Union Pacific Railroad (UPRR) right-of-way at Powell Street and 40th Street. The vehicle bridge at 40th Street has a painted bike lane but doesn’t qualify as usable by people of all ages and abilities. The Powell Street bridge does not allow bikes at all.

There was a need for a pedestrian and bike-only bridge somewhere in the middle, especially with the rapidly growing Bay Street Center mixed-used development on the east side of the tracks. The city’s Horton Landing Park project near Bay Street Center and the Emeryville Greenway—completed shortly after the bridge—-provided the necessary final push. A transformative project like it couldn’t meet its goals with poor pedestrian access.

Now, a 230-ft single-span bridge across the tracks provides that long-overdue link and boosts Emeryville’s walkability. Its combination of an S-curved deck and asymmetrical single tied-arch creates a striking image while resolving complex site conditions.

"Steel is the right material to build this bridge. It provides a limited structure depth between the top of the deck and the bottom of the structure while still providing a clearance over the top of the railroad."

A detailed construction management plan was necessary to oversee the project’s complex construction on a site near and over an active railway corridor for numerous daily freight, Amtrak, and Capitol Corridor trains, plus the UPRR train yard. Additionally, the project required UPRR-specific agreements, permits, and flagging responsibilities that were tracked and followed carefully.

The design and construction team worked closely with stakeholders to plan and schedule the bridge assembly outside of the UPRR right-of-way in the future Horton Landing Park. Deck and arch components were welded and bolted together, and temporary towers ensured the appropriate geometries conformed to the design. Full assembly took place at the temporary Horton Landing Park staging area, and the completed bridge was lifted into place over the tracks under the tightly restricted timeline.

Owner: City of Emeryville, Emeryville, Calif.

General contractor: Ghilotti Construction, Inc., Santa Rosa, Calif.

Structural engineer: Biggs Cardosa Associates, Inc., San Francisco

Steel team:

Fabricator/detailer: Steel Girder LLC dba Stinger Bridge and Iron, Coolidge, Ariz. *AISC full member; AISC-Certified fabricator and erector*

Detailer: SSP Engineering, Queen Creek, Ariz. *AISC associate member*

Bender-roller: Albina Co. Inc., Tualatin, Ore. *AISC associate member*

Erectors: Stinger Bridge & Iron *AISC full member; AISC-Certified fabricator and erector*; Adams & Smith, Lindon, Utah *AISC associate member; AISC-Certified erector*

Visit aisc.org/prizebridge to learn about past winners and to submit your project for the next Prize Bridge Awards.